That black plastic membrane under a concrete slab is there for a reason. Join our #StructuralWhyFile to find out why you need a vapour barrier under a concrete slab in Australia.

Why do concrete slabs need black plastic under them? Well, there are some great reasons. Let’s find out why.

Vapor Barriers are Not for Waterproofing

So before we begin I just want to be clear that this session is not about waterproofing concrete slabs and it isn’t about protecting concrete slabs from aggressive soils.

Waterproofing a slab on ground is quite a complex subject. To create a waterproof ground slab you’ll probably need to engage a specialist waterproofing company like Waterstop Solutions in Brisbane.

Vapour barriers are the black (or orange) plastic that builders put under residential house slabs. They do this for two main reasons:

- to prevent moisture from the soil permeating up through a slab and into a house (also known as rising damp); and

- to reduce the amount of water in the wet concrete being sucked up by the dry ground when the concrete is first poured.

How do you install vapour barrier under a slab?

To install a vapour barrier, roll out the roll of black plastic on top of the compacted sand subbase and before placing your slab on ground reinforcement.

A vapour barrier must be installed as follows:

- lap not less than 200mm at all joints.

- tape or seal with a close-fitting sleeve around all service penetrations.

- fully sealed where punctured (unless for service penetrations) with additional polyethylene film and tape.

Waffle slabs require vapour barriers too and here are some photos that show a few waffle slabs with vapour barriers – again before the concrete is poured.

Is a vapour barrier necessary under a concrete slab?

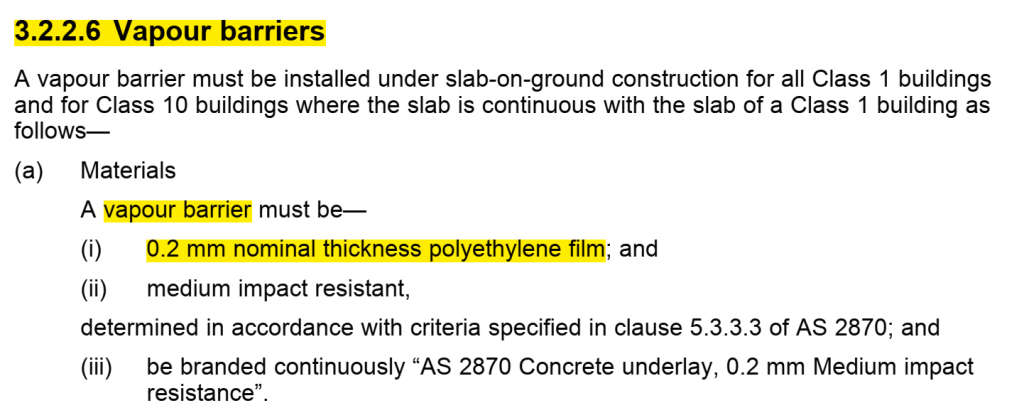

The requirements to have a vapour barrier under a concrete slab come from the NCC – the National Construction Code (Australia) (which is free when you register) and the Australian standard AS2870 for residential footings and slabs (which you have to buy).

So yes, a vapour barrier is required under a concrete slab for a Class 1 building (a dwelling) and for Class 10 (eg a garage) where the slab is continuous with the dwelling.

In New South Wales, Clause 3.2.2.6 of the National Construction Code requires the damp-proofing membrane to be 0.2mm polyethylene HIGH impact resistance and branded continuously “AS 2870 Concrete underlay, 0.2 mm High impact resistance”.

There is no excuse not to comply and we join the call for ALL certifiers to be checking that the damp-proof membrane complies with the current requirements of the NCC (and AS2870).

Do you need a vapour barrier under a shed slab?

No. You don’t “need” a vapour membrane under a shed concrete slab but it is still a good idea to install one.

In fact, most professional shed slab builders will install a polyethylene membrane under a shed concrete slab even if it is not specified.

The reason is that the vapour barrier stops moisture from the wet concrete escaping into the ground under the concrete. This creates a stronger concrete shed slab and when you’re a professional concreter you want your customers to have the best concrete slab you can pour for them.

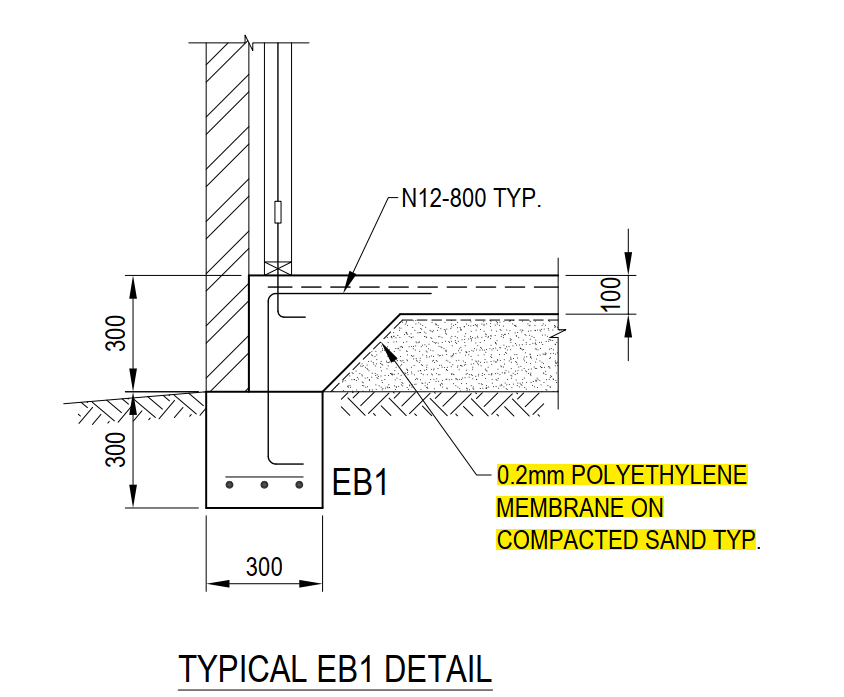

How is a Vapour Membrane Shown on Engineering Drawings?

When we call vapour barrier in our drawings we call it up as 0.2mm thick polyethylene membrane. We show it on top of a 50mm layer of compacted sand to make it easy for the builder to have the underside of the slab nice and flat.

For a full set of sample engineers drawings have a look at this page:

Sample Structural Engineering Drawings

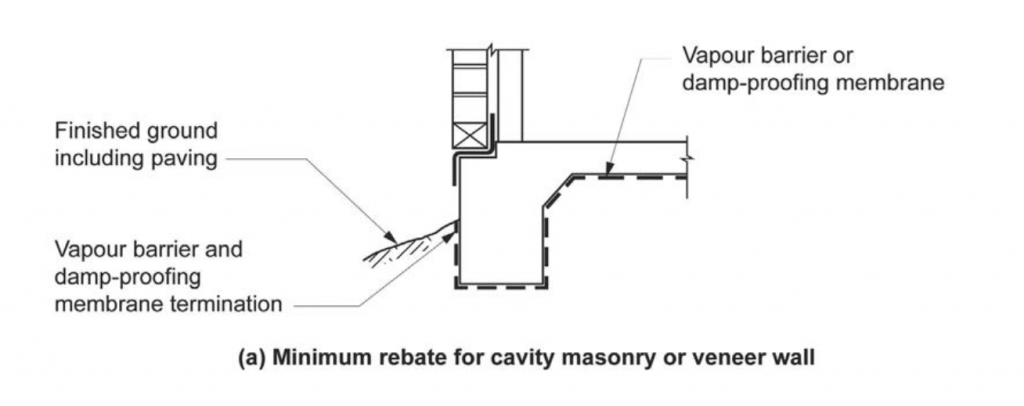

Figure 3.2.2.3 of the NCC shows clearly that the vapour barrier should lap up the outside edges of the slab:

Where can You Buy Vapour Barrier?

If you need to buy vapour barrier you can get it from your local hardware store such Grunt Black 200um Heavy Duty Builders Film – which is an extra heavy-duty builders plastic.