What is Abelflex?

The technical (confusing) answer: Abelflex is a closed-cell, cross-linked, 100% polyethylene foam expansion joint and space filler strip.

This means that Abelflex is a plastic foam that has bubbles in it that aren’t linked so water can’t run through it.

It’s made from the same sort of foam used to make pool “noodles” – so it’s buoyant. The air bubbles mean it is spongy and compressible so it’s useful for creating a space in concrete that can close up if needed.

So Abelflex is simply the proprietary product name for a foam filler that is 100mm high x 10mm thick or 150mm high x 10mm thick. It comes in rolls up to 25m long and is used in concrete work.

What is Abelflex Used For?

The primary purpose of Abelflex is to create a gap in new concrete. So Abelflex is cast into the concrete and left there.

Did you get that? Abelflex is used to make gaps in concrete.

The gap is useful when structural engineers don’t want fresh concrete to stick to existing structures or they want the fresh concrete to expand or shrink freely without affecting (pushing on) adjacent structures (including walls, other concrete, brickwork, and pipework).

Abelflex also allows new driveway and patio slabs to rotate slightly (if there is slab movement or slab heave) without cracking.

Structural engineers sometimes use it with steel dowels if they want the new concrete to flex differently to existing concrete but want the surface to stay level (or flush) because trip hazards are bad.

Finally, Abelflex is often wrapped around pipes before concrete is poured so that the pipes don’t break if there is slab heave or ground settlement.

Specific Feature of Abelflex

The specific features that make Abelflex useful on site are:

- It has an adhesive backing which makes it perfect for sticking to

Abelflex in a roll walls around the outside edges of a new concrete slab.

- It has a 10mm high tear-off strip that can (should) be removed and filled with a flexible sealant.

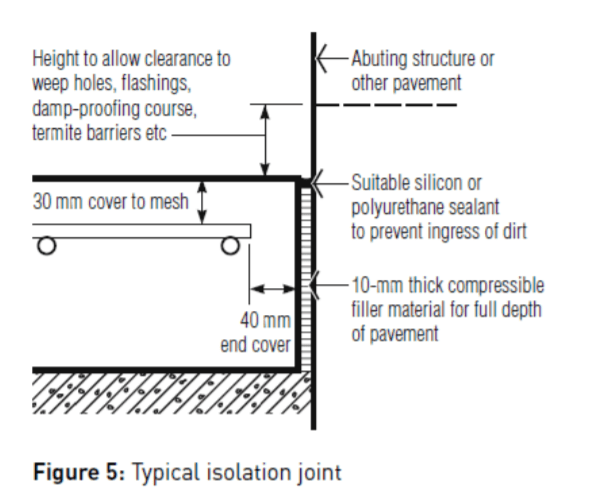

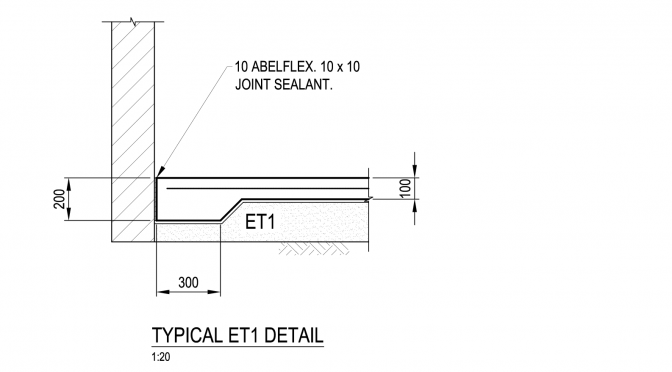

The technical term structural engineers use for the gap made by Abelflex is an Isolation Joint.

One Useful Tip

The tear-off strip on top of Abelflex is there for a reason that is often overlooked. The tear-off strip needs to be removed after the concrete has cured and the remaining gap filled with flexible sealant (Sika-flex or similar).

If you see Abelflex and it hasn’t had the strip removed and filled with sealant – that is a builder’s defect!

When a concreter is tasked with installing a carport slab or walkway slab, once the concrete is poured and cured the concreter never comes back.

If Abelflex is used and a sealant joint is not installed, the job is only half done. Get your builder or your concreter to install the Abelflex joint properly.

Why?

Abelflex DOES NOT seal the gap between a structure and a walkway slab. If you don’t seal the gap between a concrete slab and an existing structure, water can run down the gap and into the footing and could result in slab heave.

If your builder hasn’t done everything within their power to prevent slab heave, then they could be liable for repairing your house.

For the sake of installing some sealant, please make sure the tear-off strip is removed and replaced with a flexible sealant.

Where Can You Buy Abelflex

A quick Google found these Abelflex suppliers in Brisbane:

Don’t forget that Abelflex is a proprietary name. Other manufacturers supply similar products that are acceptable – particularly if their features match the features specified above. A typical example of a similar product is the product available from Parchem called Jointflex.

Abelflex is used to make gaps in concrete

So if your engineer has specified a product like Abelflex, it is there to make a gap in the concrete.

28 replies on “All About Abelflex (A Story about Joints)”

How does the bitumen impregnated felt compare to ableflex foam? Does it function the same way to an equal performance standard? I personally like the look of it better as it seems to compress at the top which seals the gap that no one ever seem to fill with sealant. I will be butting pool coping directly up against a garage slab. Probably advisable to seal in this situation.

Hi,

I am about to use the join in swimming pool base that is up against the plastic dincel wall 150 mm with the stick on.

The concrete slab will abut up to that Abelflex, by then removing the 10 mm strip , cleaning the join thoroughly and then applying maxi-seal flex to the join. Do you have any other advice before I commit to the job please, i.e. , a preparation onto the plastic before i stick it on ?

Kind regards Wayne

Hi Wayne

So long as the joint sealant will stick to the Dincel plastic then it won’t matter if the Abelflex adheres to the Dincel or not. The finished visual aesthetic will be the nice neat sealant joint. The concrete slab can expand and contract into the void created by the Abelflex and the joint sealant will flex also. Sounds like you have it covered!

Matt Cornell

I have unsealed ableflex joints in my driveway which I would like to seal with polyurethane. However the ableflex is almost flush with the surface and the tear off strip is not there. How can I cut the ableflex away to allow space for the polyurethane sealant? I suppose I will need to try and hack it away with a Stanley knife. Or the more fun but less acceptable way would be to melt it away with my flame weeder tool. Any ideas?

Officially, I would have to discourage the use of the flame weeder unless you also want to appear on Tik Tok.

I think a knife will be your best (and still not necessarily the safest) option. My idea would have been just to use a round rod to push the Abelfelx down in the groove – it is compressible after all.

Matt Cornell

Hi. I have recently built a new house and completed concreting around the house. The concretor has not put abiflex on one side of the house. He said that the house is built on the entire slab and there is no gap left to install the abiflex. He has installed the abiflex around the other sides of the house. The builder completed his 90 day warranty check and dismissed the 25 year warranty on the ground that the concretor has not installed abiflex on one side of the house. Could you please help me here?

Hi Matt , Have you seen Greenzone Termite and Insect Barrier ?

Hi Matt Greg Brown here (from Mackay) we are getting a fibreglass pool installed at the moment and I asked the boys why they are installing the abelflix upside down, they said it doesn’t have to be sealed, the abelflix is the seal. Is there a code that I can provide for them thanks in advance

Greg

The Cement and Concrete Association manual for Residential Concrete Driveways and Paths has a detail for a “Typical isolation Joint” and it clearly shows the need for a “Suitable silicone or polyurethane sealant” on top of the “10mm thick compressible filler material”. I’ve added the detail into the blurb of this article and also a link to the manual. Hope this helps.

Matt Cornell

Hi

I had some concrete recently laid around the house and they have not installed the ableflex correctly (using the tearoff strip and adding sealant). The foam is flush with the surface minus the tear out strip. It looks as though they have torn the strip off before installing.

Is there any way post concreting to fix this issue? Is there a way to cut down the ableflex so the sealant can be added/done?

Sorry!

Spelling should be Abelflex!

I have the same problem and I’m not sure how to cut the Ableflex foam back to allow space for the polyurethane sealant. I suppose I need to use a Stanley knife.

Is Abelflex flexible enough to install following the contours of Zinculume shed wall cladding to protect it against the concrete floor pour ?.

My shed builder says that the wet concrete pour won’t corrode the the Zinculume wall cladding ,I disagree

I think you’d be better off trimming the steel cladding off just above slab level. Perhaps get a local engineer to speak to your concreter about termite protection and corrosion protection.

I think you can also spray the coro / zinculume with WD40 Linoleum or similar spray and that prevents the concrete adhering to / rusting the metal (assuming water will not run down the iron / concrete… ie. undercover). and after the slab is poured give it another anti-rust spray periodically.

Matt

Great information. What is the best non mechanical means for removing ableflex that has been incorrectly stuck in concrete. We tried acetone and it does not work. Your answer will be appreciated.

Many thanks.

Roger

Hi Matt, I want to use abelflex for a different purpose than joint seal. In particular a little flexible box to protect some camera equipment and need to glue it together. Do you know or can you recommend a way to bond different pieces of abelflex together? thank you

Hi Obob

Abelflex comes with a sticky back so you ‘could’ use the sticky face to join multiple sheets, BUT

why don’t you speak to these guys or a similar supplier:

http://www.pjbowers.com.au/foam.html

To get the 10mm thick Abelflex they cut it down from a big block. That sounds like a better starting point to me.

Matt

Hi. I have recently built a new house and wanted to do concreting around the house. The concretor has not put joint foam at one complete side. He said that slab was irregular so foam is not required. He has concreted to hide the slab. I am doubtful if this is actually the right practice. Could you please help me here?

Hi Kari

Can you send me some photos please? It’ll give me a better idea of what’s going on. Can you upload them on the get a quote page please?

Matt Cornell

How would this stuff go when putting in a drainage channel? The one I have bought recommends an expansion material between it and the concrete to allow for fitment and removal of the grates (http://www.everhard.com.au/wp-content/uploads/2016/04/EasyDRAIN-Installation-Instructions.pdf). Would it be best to remove the tear off strip and use the other 90mm?

Hi Andrew

I had a look at the reference you included. I think this installation manual gives a better idea of how the grated drain should be installed with Abelflex or some other expansion joint material:

http://www.acoaus.com.au/pdf/site_installation_manual.pdf

The tear off strip should be left on for the concrete pour, torn off and filled with a joint sealant as per my original post.

Matt

Thanks Matt.

That’s a really informative manual, especially for someone dealing with this for the first time.

Much appreciated.

Very useful page as I have a small concrete repair job to do – thanks!

Well explained! It is ideally suited for joints in sidewalks, driveways, streets, and single- and multi-level floor slabs. Due to its unique self-sealing characteristic, no subsequent joint sealing is required.

Thanks for the comment Perci. Unfortunately I disagree about the self-sealing characteristic of Abelflex. This is a common misconception – extra sealant IS required when Abelflex is used. Abelflex and its competitors come with a tear off strip that should be removed and filled with joint sealant. That is their real benefit – they make it easy to install joint sealant where they have been used in a joint.

Without joint sealant you DO NOT have a water seal.

Check out these links for information from the manufacturers.

http://www.parchem.com.au/public/pdfs/data-sheets/Jointflex-TDS.pdf

https://www.tilersonline.com.au/files/data-sheets/davco-Abelflex%20Datasheet%20v1.1.pdf

Matt Cornell

that directly contradicts the instructions above about tearing off the strip and sealing.

Sorry, Matt Cornell’s reply makes mine redundant.